Table of contents:

Common "Iron" Core Power Transformers the kind we have.

Executive Summary: Raising the applied frequency from 50 Hertz to 60 Hertz is just fine.

Going the other way, from 60 Hertz design to 50 Hertz usage, is a *BIG DEAL*. The applied input voltage should be reduced to 5/6 name plate rating or bad things can/will happen. They need about 20 % more "iron" to work at 50 Hertz.

Reference - most any transformer book and also

| AC Frequency | Two Pole | Four Pole | Six Pole |

| 60 Hertz | near 3600 RPM | near 1800 RPM | near 1200 RPM |

| 50 Hertz | near 3000 RPM | near 1500 RPM | near 1000 RPM |

Actually, the near synchronous motors "slip" a little, and up to about 5% under full load. So the full load speed of a 4 pole motor excited at 60 Hertz is about

Motor trivia

Three phase motors have high starting torque with no artificial help, the internal

field actually rotates giving the rotor a good twist. So called split phase motors,

as plugged into the usual wall socket, have an internal field that oscilates

back and forth, providing no torque until the rotor gets to spinning to say 15 % rated speed.

These split phase motors are started in three common ways,

Like transformers, a near synchronous motor designed for 60 Hertz

must have its input voltage reduced to 5/6 of rated voltage for 50 Hertz

operation. The rotational speed will be reduced to 5/6.

Rated power and starting torque will also be reduced.

On the two types above, the starting element is switched out when the rotor reaches about

50% rated speed to save damage of the capacitor or resistive element.

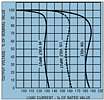

Ferroresonant Power Conditioners

which smooth and regulate the voltage of AC.

Constant Frequency, Input vs Output Voltage, varying loads

Constant Load, varying frequency

|